Checker Sensor

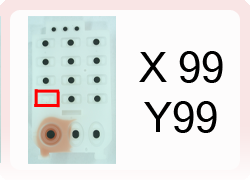

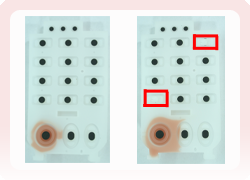

To check logos or significant points required to be checked. It can check multiple points.

Able to identify the ranges of logos or significant parts

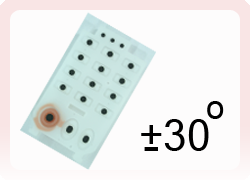

It can identify the errors even in a picture with 30 degrees tilt.

Able to check multiple points.

Its database can be linked with SAP or ERP system.

Specs

|

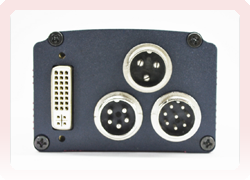

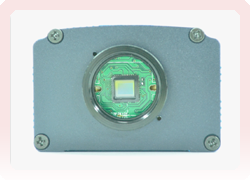

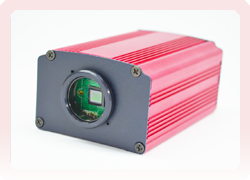

Camera

|

Body

|

Customization Option

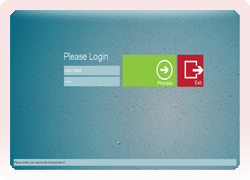

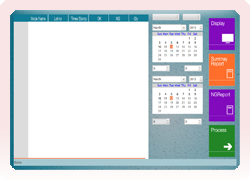

| Program Multiuser It is the system to classify right in use of programs which has 2 groups, i.e. an operator and administrator. ReportV1 To report number of inspected work pieces, number of good and faulty pieces. ReportV2 To report faulty pieces by identifying what is the fault and positioning the faulty part in the pictures. Remote/Wire Able to control the sensor by another computer through the LAN system without monitor at the sensor. Remote Monitiring support It is a support system from the company for troubleshooting purposes through the Internet, so your problems can be solved rapidly and easily. |

| Hardware Memory 32 GB To double areas for saving data,faulty work pieces and various reporting systems. Remote/wifi It is a wireless network. Lens Machine Vision Lens 5 50 mms to ensure multiple sizes inspection. Lighting System It is a lighting system for inspection. IO Module It is a system for interfacing PLC or sensor with other IOs. |